Hammer Lug unions

HAMMER LUG unions – general information

HAMMER LUG unions, or WECO couplings, as they are called, allow for quick connecting the pipelines and flexible hose assemblies in the oil and gas industry . They are popularly used on onshore and offshore drilling rigs to transfer petroleum, gas, drilling mud, cement, water, air and many other media.

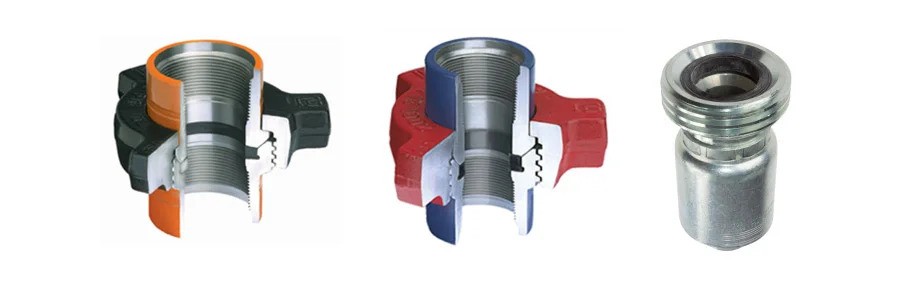

As the very name says, a hammer is used to tighten and loosen HAMMER LUG unions – no special tools are needed. HAMMER LUG union consists of a coupler with a male thread and inner cone (female half), a ball-shaped fitting (male half) and a female thread nut which tightens the the ball-shaped fitting with the cone of the coupler. A close contact of the ball end with the cone (depending on the type) provides a primary sealing (metal/metal), or the sealing is achieved via additional rubber seal (o-ring or lip seal). The coupling (the nut and coupler) comes with a trapezoidal ACME thread (standard or modified). They connect to an installation with NPT female thread end connection or via weld-in connections.

HAMMER LUG couplings are manufactured from heavy duty steel forgings: carbon steel ASTM A105 (for working pressure below 414 bar – 6000 PSI) or chromium-molybdenum steel 4130 (for higher pressure values).

HAMMER LUG unions are designated with numbers (Figures) corresponding to particular types. Each figure regardless of its size, is intended for the particular working pressure and application, and the components of the union are painted with a specific colour to make identification easier. HAMMER LUG union sizes range from 1″ to 12″ (depending on the type of the union).

HAMMER LUG unions are of a very strong construction. They are manufactured of certified materials only, with full traceability. Working pressure at ambient temperature ranges from 35 bar (500 PSI) to 1378 bar (20000 PSI). They are type approved by Det Norske Veritas (DNV). HAMMER LUG couplings designed for hydrogen sulphide applications (H2S), resistant to hydrogen embrittlement, compliant to NACE MR-01-75 are also available.

Hammer Lug hose fittings

HAMMER LUG hose fittings – HAMMER LUG couplings can be integrated with hose tails or screwed onto appropriate fittings with the used of NPT thread end connection. Depending on application and working pressure, industrial hoses for water (e.g. MONTANA 20 bar), hoses for petroleum products (e.g. FUEL HARDWALL 30 bar), hoses for concrete (e.g. SHANNON 80 bar), rubber hydraulic hoses (e.g. R15 420 bar) can be used with corresponding HAMMER LUG coupling types e.g. Figure 206 (138 bar), Figure 1502 (1034 bar).

Hammer Lug integral fittings and pup joints

HAMMER LUG pipe unions – integral design pipe fittings (no welded parts) for petroleum, gas, drilling fluid, water, cement, air, etc. Widely used in flushing, fracturing, cementing operations, wireline services, choke and kill lines, etc. They are made of chromium-molybdenum steel in sizes ranging from 1″ to 3″, in various configurations – elbows, tees, crosses, pup joints, with HAMMER LUG couplings or NPT thread end connections. Working pressure in accordance with HAMMER LUG union type, e.g. 414 bar (6000 PSI) for Figure 602, 1034 bar (15000 PSI) for Figure 1502. Sour gas unions are available for hydrogen sulphide service.